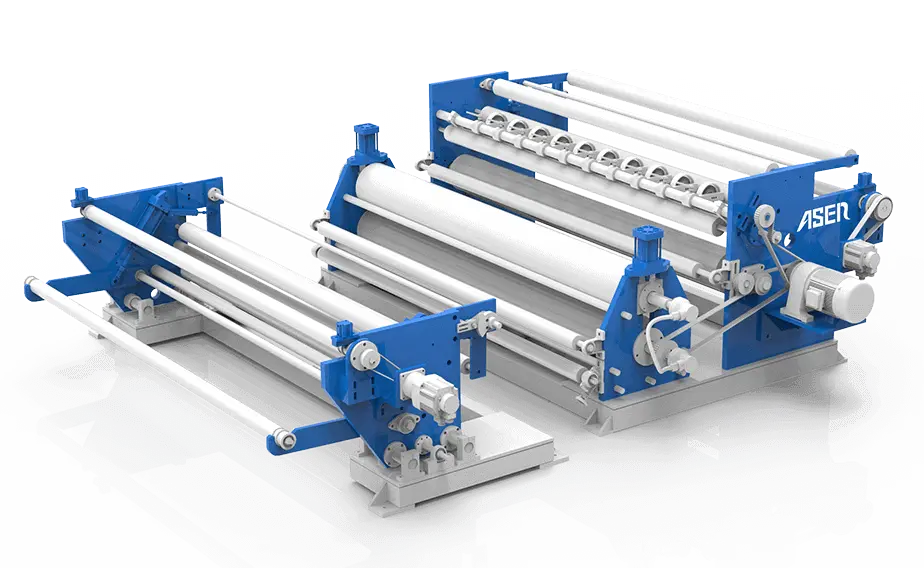

Nonwoven Punching Machine

ASEN provides you with one-stop service and turnkey solutions for Nonwoven fabric extrusion laminating machine, Film laminating machine, Offline slitter, Fabric joining machine, Fabric folding machine, Nonwoven punching machine, etc.

Nonwoven Punching Machine

- Equipment function: film cold punching, hot punching, hot perforation, foam.

- Punching materials: various packaging plastic films, paper, composite films, copper foil, aluminum foil, non-woven fabrics, automotive sound insulation panels, etc., especially suitable for punching of OPP, PE, PET, desiccant, deoxidizer packaging composite films;

- Perforation shape: micro air hole, large air hole, perfect circle hot hole, ellipse hot hole, click gasification hole, etc.; different shapes of air holes can also be customized according to customer requirements.

- Hole size: 0.03 ~ 20mm;

- Micro-tension synchronous rewinding performance reaches the level of similar machines in Germany and Japan;

- The heating roller reaches a high temperature of 300 degrees;

- Needle roller: The needle roller is processed by foreign high-precision equipment. Advantages: The density of needle arrangement is high, the error of needle center distance is not more than 0.001 mm, and the concentricity of needle tip surface is ≤0.005MM.

What is best for you?

Get the right nonwoven line for your application

①

Arrange a consultation

②

Put your nonwoven machine into operation

③

Become a sought-after nonwoven supplier

More info or customized solutions?

We are there for you