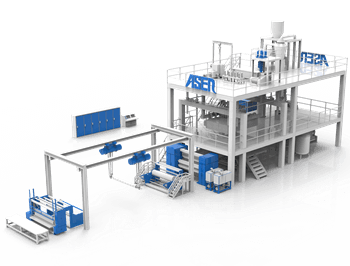

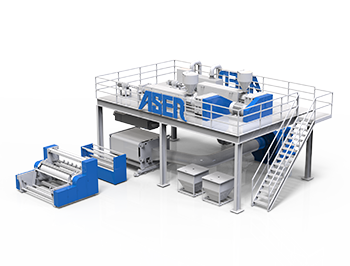

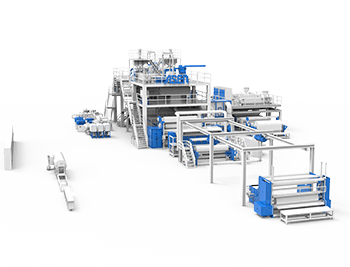

a powerful nonwoven machines manufacturer in China

produce high-quality

nonwoven machines

to Explore the greater

nonwoven market

it's good to know

Why many nonwoven suppliers choose ASEN

ASEN was established in 2009, we use our professional non-woven knowledge to provide customized production services and comprehensive technical support to different customers around the world.

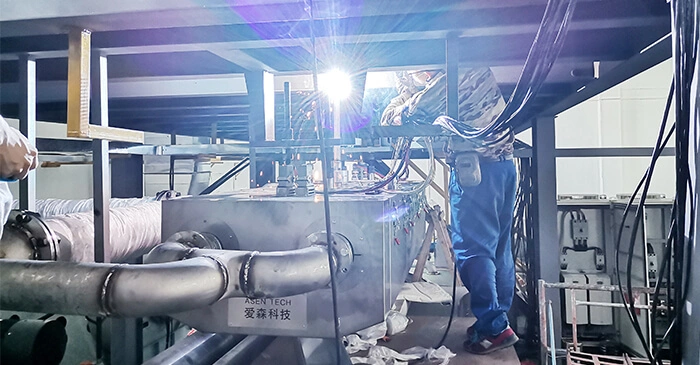

We have a factory covering an area of more than 10,000 square meters and a professional nonwoven machine technical team. Therefore, the entire production cycle of ASEN’s nonwoven production line, from the initial design to the construction of the machines, is carried out in ASEN’s own factory, for which we can conduct operational testing of the non woven production line before delivery.

With our professionalism and serious and responsible attitude towards nonwoven machines, some well-known non-woven suppliers around the world are willing to cooperate with us.

What People Say About Us

“The guys over at ASEN not only provided quick estimates, an honest timetable, and professional courtesy, but also quality work that exceeds their fair pricing. I recommend them for anyone’s next project.”

it's good for you

Get More Support From ASEN

Design

Customize customer’s sketch for free

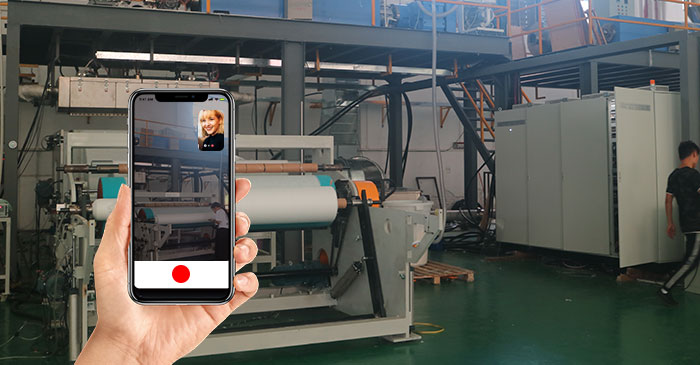

Tracking

Provide visual production tracking

Installation

Support on-site installation training

Technology

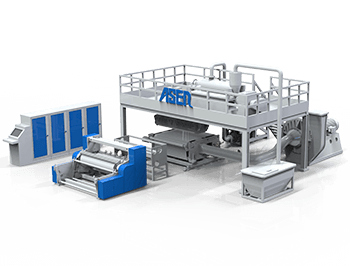

Produce density of nonwoven fibers reach 1.3 den

Experience

Own the technology from component to bicomponent with 10+ years

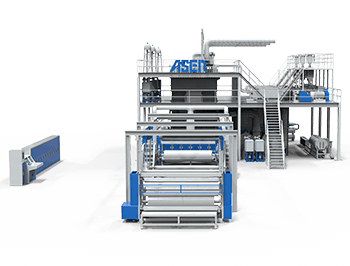

Get the best out of machine productivity

take quality and profitability to the new level

What is best for you?

Get the right nonwoven line for your application

WHAT CAN WE DO FOR YOU?

try our best to serve you

Technical Consulting

Live Broadcasting

Producing

Online Assistance

Installation & Debugging

Shipping

More info or customized solutions?

We are there for you